Innovating Power and Technology: A Deep Dive into Radial Feeders, THT PCB Assembly, and EMS Factories

This article delves into the intricacies of electrical power distribution through radial feeders, the precision involved in Through-Hole Technology (THT) for PCB assembly, and the operational excellence within Electronic Manufacturing Services (EMS) factories. Join us as we explore the synergy between these critical components in the world of electronics manufacturing.

Understanding Radial Feeders in Power Distribution

In electrical power distribution, radial feeders serve as the arteries that deliver energy to consumers. The design and implementation of these feeders affect reliability, efficiency, and safety. This chapter will explain radial feeder systems, their topology, and how they are a cost-effective solution for both medium-voltage and low-voltage networks. We’ll also discuss key design considerations such as mains voltage ratings and protection against electric shocks, and explore how radial feeders handle the distribution from substations to end customers.

The Role of THT PCB Assembly in Modern Electronics

Through-Hole Technology (THT) PCB assembly remains pivotal in modern electronics due to its benefits in durability and repairability. In THT, components are mounted by inserting leads into pre-drilled holes on a PCB, then soldering them in place. This solid mechanical connection makes electronic devices robust and easier to modify or repair compared to Surface-Mount Technology (SMT). When discussing pin headers in THT, two types are prominent: shrouded and polarizing key headers. Shrouded headers provide a cover that helps prevent misalignment and supports correct orientation, enhancing connectivity reliability. Polarizing keys ensure correct orientation and insertion of the header, preventing potential damage or disconnects caused by incorrect placement. These header options play a crucial part in the reliability and functionality of THT PCB assemblies, making them an enduring choice in electronics manufacturing.

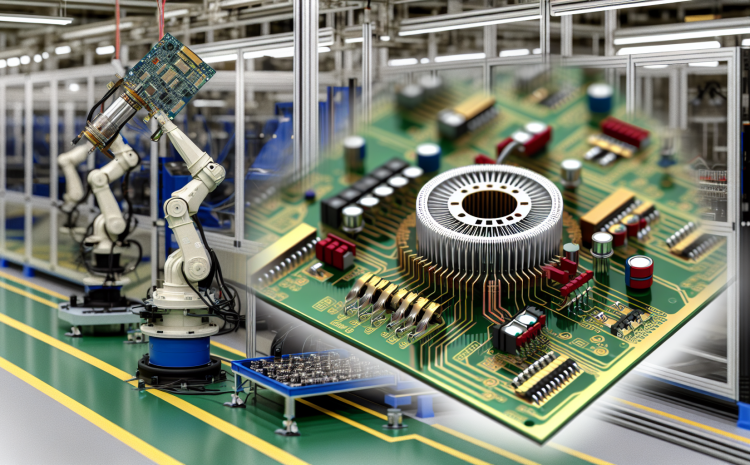

Electronic Manufacturing Services: The Cornerstone of High-tech Production

EMS factories are vital nodes in the electronics supply chain, harnessing a network that spans the globe. Operating in strategic locations, these factories optimize logistics and access to markets. Their production capabilities are diverse, manufacturing everything from advanced polymers used in high-performance electronics to precision components for automotive safety systems. This expansive range is possible due to sophisticated acquisition strategies for raw materials and state-of-the-art manufacturing technologies. The integration of these processes allows EMS factories to swiftly adapt to changing market demands and maintain their pivotal role in the dynamic landscape of electronics manufacturing.

Innovation and Efficiency: EMS Advancements in Technology

EMS advancements in technology have significantly emphasized enhancing material properties and process efficiencies. By incorporating hot-melt adhesives that swiftly bond components at lower temperatures, EMS factories significantly reduce energy consumption. Moreover, the adoption of powder coatings that can endure harsher environmental conditions without degrading ensures the longevity and reliability of electronics. These modifications not only boost the performance of everyday devices like smartphones and home appliances but also cater to the more demanding conditions of automotive electronics, which require higher resistance to vibrations and heat. These improvements in EMS factories’ operational strategies ensure that the electronic components meet stringent quality standards while supporting sustainability initiatives.

The Future of Power Distribution and Electronics Manufacturing

As we progress into the future, radial feeders are anticipated to become smarter and more dynamic, aligning with the growth of automated controls and smart grids. These advancements will likely enhance the ability to predict and manage load fluctuations and power quality in real-time, improving overall system efficiency and reliability. Similarly, THT (Through-Hole Technology) PCB assembly is being refined with the integration of automated optical inspection and 3D solder paste measurement to ensure higher accuracy and efficiency in electronic circuit productions. As for EMS (Electronic Manufacturing Services) factories, the focus is shifting towards more modular and scalable designs. This facilitates quick adaptation to the manufacturing demands of various industries, including consumer electronics and automotive sectors, while also supporting environmental sustainability through waste reduction and energy-efficient practices. The incorporation of IoT and advanced data analytics into EMS environments will drive predictive maintenance, resource optimization, and better supply chain visibility, ensuring a more responsive and resilient manufacturing process.

Conclusions

In conclusion, radial feeders, THT PCB assembly, and EMS factories are interconnected facets of the electronics industry, each contributing to the efficiency and advancement of power distribution and manufacturing. By examining their individual roles and collective impact, we gain insight into the critical processes that sustain and innovate within the realm of modern technology.

发表评论