Revolutionize Your EMS with Precision SMT automatic Tape Splicing machine

Enhanced Efficiency: How Automatic Tape Splicing Streamlines EMS Production

The relentless march of technological advancement demands ever-increasing efficiency from every sector, and the Electronics Manufacturing Services (EMS) industry is no exception. For years, the consistent, reliable feeding of component reels to Surface Mount Technology (SMT) lines has been a surprisingly persistent bottleneck. Traditionally, this task has fallen to manual intervention – a process prone to downtime, material waste, and, ultimately, increased production costs. However, a new generation of automatic tape splicing machines is poised to revolutionize this critical stage, offering a pathway to significantly enhanced efficiency and a more streamlined EMS operation.

Consider the typical scenario: a component reel nears its end, halting the SMT line. An operator must then meticulously align and join the trailing tape to a new reel, a process demanding precision and skill. Even with experienced technicians, this interruption, however brief, accumulates over the course of a shift, a day, a week – translating into lost production time and diminished output. Furthermore, the manual splicing process isn’t always perfect. Misalignments can lead to component misplacement, necessitating rework and further exacerbating delays. Beyond the immediate impact on the line, there’s the issue of material waste. Imperfect splices often require discarding a portion of both reels, adding to the financial burden.

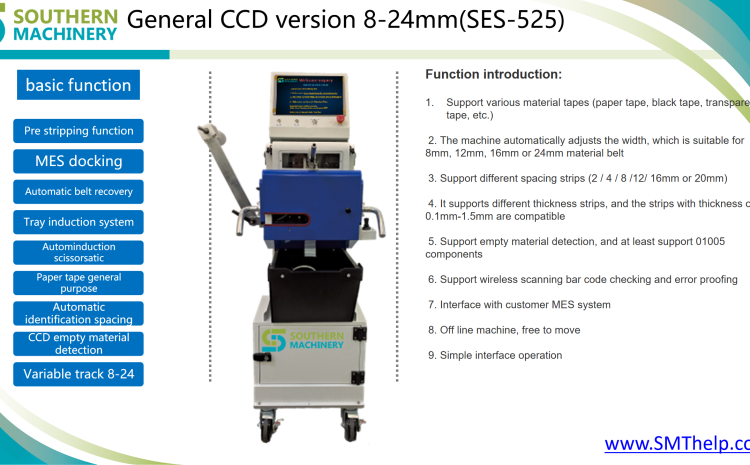

Now, imagine a system where this interruption is virtually eliminated. That is precisely the promise of precision SMT automatic tape splicing machines. These sophisticated devices utilize advanced vision systems and robotic precision to seamlessly join component tapes, often completing the splice within seconds, and with a level of accuracy far exceeding manual capabilities. Consequently, SMT lines can maintain continuous operation, maximizing throughput and minimizing downtime.

But the benefits extend beyond simply keeping the line running. The consistent quality of an automated splice dramatically reduces the likelihood of component misplacement, leading to fewer rejects and a higher first-pass yield. This, in turn, lowers rework costs and improves overall product quality. Moreover, these machines are designed to minimize tape waste, utilizing the full length of each reel and contributing to a more sustainable manufacturing process.

Indeed, the integration of automatic tape splicing isn’t merely about automating a single task; it’s about fundamentally rethinking the flow of materials within the EMS environment. By removing a significant point of potential disruption, these machines allow for a more predictable and controlled production process. This predictability is crucial for accurate forecasting, efficient resource allocation, and ultimately, meeting increasingly demanding customer deadlines. As EMS providers strive to offer faster turnaround times and greater flexibility, the ability to maintain continuous SMT operation will become increasingly vital. Therefore, embracing this technology isn’t just a step towards enhanced efficiency, but a strategic investment in the future of competitive advantage.

Minimizing Downtime: The Role of Precision SMT Tape Splicing in Continuous Manufacturing

The relentless march of modern electronics manufacturing demands an unwavering commitment to uptime. In the Surface Mount Technology (SMT) realm, where components are placed with microscopic accuracy at breathtaking speeds, even momentary interruptions can ripple through the production line, impacting output and profitability. Consequently, the seemingly small detail of component tape feeding has emerged as a critical area for optimization. For years, manual tape splicing – the process of joining the ends of component carrier tapes to ensure continuous supply to pick-and-place machines – represented a vulnerable point, a potential source of delay and inconsistency. However, the advent of precision SMT automatic tape splicing machines is fundamentally altering this landscape, offering a pathway to truly continuous manufacturing.

Traditionally, a technician would halt the SMT line when a tape reel neared depletion. This involved carefully aligning the tape ends, applying splicing tape, and meticulously inspecting the joint for flaws. While skilled operators could perform this task efficiently, it remained inherently prone to human error, variations in splice quality, and, crucially, lost production time. Furthermore, the reliance on manual intervention introduced a degree of unpredictability; operator availability, fatigue, and even minor distractions could contribute to inconsistencies.

Now, imagine a system where this process is not only automated but executed with a level of precision exceeding human capability. That is precisely what modern automatic tape splicing machines deliver. These sophisticated devices utilize advanced vision systems to identify tape edges with sub-micron accuracy, ensuring perfect alignment. Instead of adhesive tape, many employ a mechanical splicing method, creating a seamless, robust joint that eliminates the risk of tape peeling or component misplacement. This transition from adhesive to mechanical splicing is particularly significant, as it removes a potential source of contamination and ensures consistent tape tension.

The benefits extend far beyond simply eliminating manual labor. Because these machines can perform splices incredibly quickly – often in under a few seconds – the SMT line can remain operational with minimal interruption. This translates directly into increased throughput and reduced cost per unit. Moreover, the consistent splice quality minimizes the risk of machine stoppages caused by component presentation errors, a common issue with poorly executed manual splices.

But the impact isn’t limited to immediate production gains. The data generated by these machines provides valuable insights into tape consumption, splice frequency, and potential issues with component reels. This information can be leveraged to optimize inventory management, predict maintenance needs, and even identify potential quality control problems upstream in the supply chain. In essence, the automatic tape splicer isn’t just a piece of equipment; it’s a data-rich node within a larger, increasingly intelligent manufacturing ecosystem.

Ultimately, embracing precision SMT automatic tape splicing is a strategic investment in resilience. It’s about proactively removing a bottleneck, minimizing downtime, and unlocking the full potential of your SMT line. As the demand for faster, more reliable electronics continues to grow, the ability to maintain continuous production will be a defining characteristic of successful manufacturers, and automated tape splicing is undeniably a cornerstone of that capability.

Quality Control & Cost Savings: Implementing Automatic Splicing for Superior EMS Results

The relentless march of technology demands ever-increasing precision and efficiency from Electronic Manufacturing Services (EMS). In this landscape, maintaining a consistently high level of quality while simultaneously driving down costs isn’t merely desirable – it’s essential for survival. For years, the seemingly simple task of joining carrier tape for Surface Mount Technology (SMT) components has been a potential bottleneck, a source of both subtle defects and surprisingly significant financial drain. However, a new generation of automatic tape splicing machines is emerging, poised to revolutionize EMS operations and deliver substantial improvements in both quality control and cost savings.

Traditionally, tape splicing has been a manual process, reliant on the skill and consistency of an operator. While experienced technicians can achieve acceptable results, the inherent variability of human performance introduces risk. Misaligned splices, inconsistent tape tension, and even minor contamination can all lead to component misplacement during pick-and-place operations. Consequently, this translates to increased rework, scrapped boards, and ultimately, a compromised final product. Furthermore, the time spent manually splicing tape is time *not* spent on more value-added activities, impacting overall throughput.

Fortunately, the advent of precision automatic tape splicing machines addresses these challenges head-on. These aren’t simply automated versions of the old method; they represent a fundamental shift in approach. Utilizing advanced vision systems, these machines meticulously align the carrier tape, ensuring a seamless and robust joint. Crucially, they maintain consistent tape tension throughout the splicing process, eliminating a major source of component placement errors. Moreover, many models incorporate enclosed splicing chambers, protecting the delicate components and tape from dust and other contaminants.

The benefits extend far beyond simply reducing defects. Consider the material waste associated with manual splicing. Operators often err on the side of caution, discarding more tape than necessary to guarantee a secure connection. Automatic splicing machines, however, optimize tape usage, minimizing waste and contributing directly to material cost reductions. This is particularly significant for expensive or specialized components where even small savings per reel can accumulate into substantial gains over time.

Beyond the immediate cost savings, the implementation of automatic splicing fosters a more predictable and reliable manufacturing process. This predictability allows for more accurate production planning, reduced lead times, and improved customer satisfaction. In essence, it shifts the focus from reactive problem-solving – dealing with defects *after* they occur – to proactive prevention, ensuring quality is built into the process from the very beginning.

Indeed, integrating this technology isn’t just about acquiring a new piece of equipment; it’s about embracing a philosophy of continuous improvement. By automating a critical, yet often overlooked, step in the SMT process, EMS providers can unlock significant gains in efficiency, quality, and profitability. As the demand for increasingly complex and reliable electronic products continues to grow, the precision and consistency offered by automatic tape splicing machines will undoubtedly become a defining characteristic of leading-edge EMS operations.

发表评论